Very Narrow Aisle (VNA) Cantilever Racking

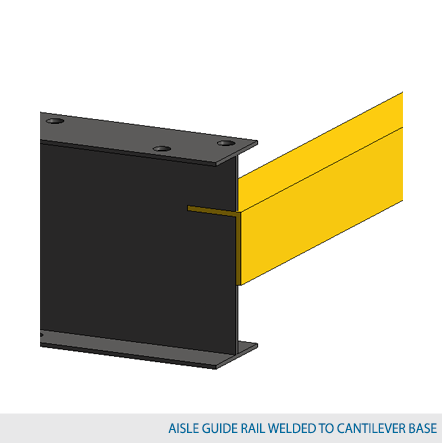

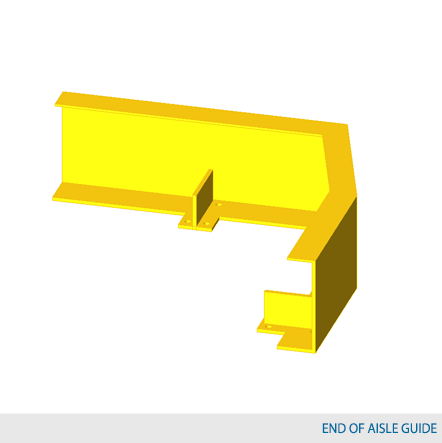

The cantilever system is paired with a guide rail which protects the columns from equipment damage. The guide rail is categorized into two categories; Installation type 1 and installation type 2. When installing type 1 the guide rail is welded on site to the cantilever rack base. The end aisle guard rail is then placed at each corner of the assembled cantilever system. These angles are welded to the end aisle guard rail which creates a continuous barrier around the assembled system. The guiderails are available in the following size: 4”x 6” x 3 /8”. The end-of-aisle guard is heavy duty. Heavy duty are manufactured as standard 8”, 10” or 12” heights and contains a welded fold of 3” along the top of the guardrail. The system offers the same versatile storage abilities as the conventional cantilever racking, but with added aisle guide rail and end-of aisle guardrail. The rails work to guide narrow aisle fork trucks through the picking aisles, allowing for faster, easier and more efficient operation. Pick precision is increased and material damage is significantly reduced.